Energy Audit

Energy audit plays important role in reducing energy bills. Industries which have allotted higher part of running cost towards energy are advised to take energy audit in their routine work timely. In energy audit detailed analysis of setup is done to understand flow of energy. Energy audit ends up with recommendations which involve low cost, medium cost and high cost investments. We can reduce energy bills up to 30% by adopting low cost investment projects and projects with less than 2 years payback period. Not only energy audit helps in saving energy but also helps to reduce impact on environment by emission of hazardous pollutants. In overall view objective of audit is same for all the industries but process of audit may changes industry to industry. In general process previous energy bills are collected. Analysis is done to identify energy conservation measures (ECM’s). After cost benefit analysis of ECM’s and action plans are prepared for implementation of ECM.

Energy management and audit is a process including Inspection, Survey & Analysis of energy flows for energy conservation in a building, a process or a system to reduce the amount of energy input into the system without negatively affecting the output(s) plugged. Energy management and audit is the quickest, cheapest and cleanest way to reduce Energy Consumption. Ecoenergies provide the best energy audit program. Ecoenergies is the best energy audit management company in India. It is a best energy audit India provider. We help to grow your business. In most existing installations, we can target up to 25% energy savings using existing offers and technologies through our step by step approach to energy efficiency. ECO ENERGIES has a comprehensive offer for Residential Buildings, Commercial Complex, Hotels, Hospitals and Group Housing societies and with Energy Efficiency Solutions that help you turn energy savings into growth. Ecoenergies provides the best energy audit program companies in india and we are the best energy audit provider in india.

Why Energy Audit

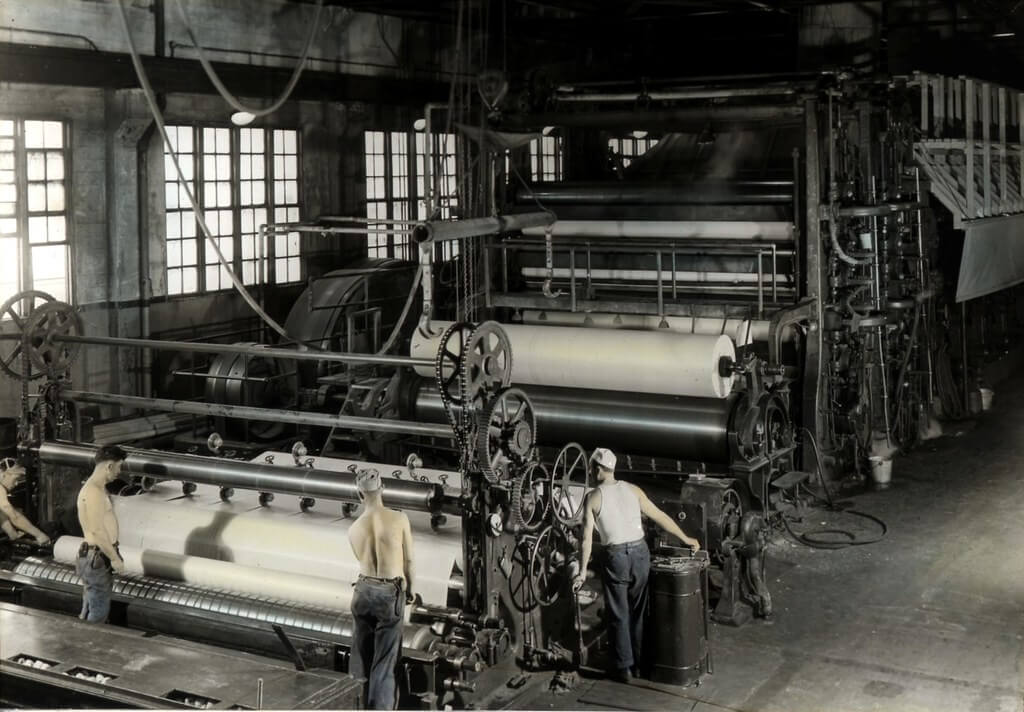

Increasingly in the last several decades, industrial energy audits have exploded as the demand to lower increasingly expensive energy costs and move towards a sustainable future have made energy audits greatly important.

Types of Energy Audit

The type of industrial energy audit conducted depends on the function, size, and type of the industry, the depth to which the audit is needed, and the potential and magnitude of energy savings and cost reduction desired.

Energy Audit Methology

Preparation for energy audit

1). Defining the audit criteria.

2). Defining the audit scope

3). Selection of energy audit team.

Why Eco Energies

Similar Work Experience

We are doing Energy Audits from last 10 years and have covered almost all types of Sectors and sites.

Qualified

Team

Are team members have varied qualification from Mechanical, Electrical & Chemical background and are BEE & AEE Certified.

National & International Accreditation

We have all the national and International Accreditation in the field of Energy Management.

Understanding Client’s Need

We define our scope based on the clients need and purpose of Energy Audit.

Energy Service Company

We are an ESCO and can take up the Implementation Projects also.

For more information please fill enquiry form.

NAMDHARI ECO ENERGIES PVT LTD

Get in touch with us

Address:

Corporate Office :

204, 2nd Floor, Block – 4, STPI, Ganga Shopping Complex (Near Botanical Garden Metro Station) Sector 29, Noida – 201303 Uttar Pradesh

Phone : 0120-4220122

Works Office :

Plot No 1, IIE ( IT park ) STPI, Sahastradhara Road, Dehradun-248001, Uttarakhand

Phone: 0135-2984024

Mobile: 9773811400 (For Products & Solution)

Mobile: 9711591550 (For only Energy Audit Enquiry)

Email: info@ecoenergies.co.in